A rotation plan involves the following steps:

- Determine your unit’s operational requirements

- Decide if you are building a block rotation or line rotation

- Develop a rotation plan

- Choose one of the template tools to build your plan

An HEU Rotation Support Specialist will assist you with any aspect of this plan. Please contact your Shop Steward or your HEU Servicing Representative to find out more.

Determining operational requirements

Operational requirements specify the unit’s needs. This is also called a baseline.

Your employer will supply you with this information.

You will want to know the following:

- Current unit/department staffing levels

- Hours and days of operation

- Job classification

- The number of employees required to be working per shift and per day

- The Shift Label (D, E, N), also known as the Icon, which is a short abbreviation used when plotting shifts on the rotation.

- Start and end times (for example 07:00-15:00,15:00-23:00 or 23:00-07:00) of all shifts

- Paid hours (for example 7.5) for each shift

- How many full-time positions are required

- How many part time positions are required

- What is the total FTE (full time equivalent) for your department/unit

Decide if you are building a block rotation or a line rotation.

A block rotation is a group of lines that have the exact same pattern of shifts, and each worker would snake through the same shift pattern, just starting at different weeks.

A line rotation is where every line may have a different pattern of shifts.

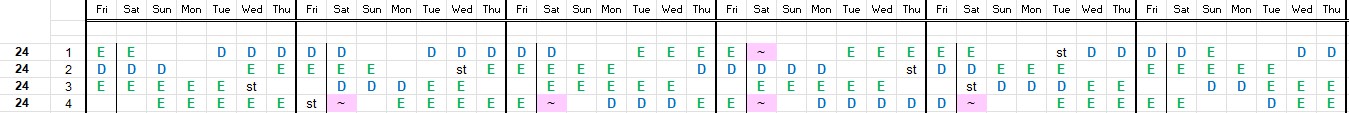

Here is an example of a block rotation. In this sample, This rotation is a 24 week wide block rotation, lines 1 through 4 all work the same shift pattern, they start/stop at different times.

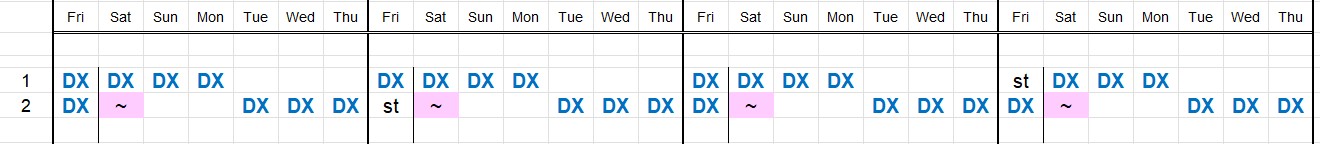

Here is an example of a line rotation. In this sample, This rotation is a 4 week wide line rotation, lines 1 and 2 each work their line with fixed shifts.

Develop a rotation plan

Your plan will determine things like:

- Number of shifts on each line, broken down for each shift in the baseline

- Number of weekends worked on each line

- Number of stat holidays on each line

Choose a template tool to build your plan.

There are three different tools to use, based on the operational needs of your worksite.

Simple Rotation tool

- You have an even baseline seven days a week

- 8 hour rotations with Days and Evenings, no Nights

- Your unit has up to 15 FTE

- Your unit has no more than 2 shift types, and everyone working them has the same start and end time. For example, days, D (7:00-15:00) and evenings, E (15:00-23:00), both shifts are the same length and the same paid hours, regardless of the start and end times.

Moderate Rotation tool

- You have the same baseline seven days a week

- There are a maximum of 6 different shift types with many different start and end times, for example, D (7:00-15:00), D8 (8:00-16:00), D9 (9:00-17:00), E (15:00-23:00), e2 (15:00-21:00) and N (23:00-7:00)

- A moderate rotation can be up to 50 FTE. Larger rotations that otherwise meet the criteria for being Simple Rotations.

- 8-hour rotations that include Days, Evenings and Nights

- Full time lines work 8 hour shift lengths, part time lines may work a few different shift lengths

Complex Rotation tool

- Rotations that are more than 50 FTE

- Rotations with uneven baselines, for example clinics run only on certain days.

- Rotations that include more than 6 shift labels

- Rotations that have a lower baseline on weekends than on weekdays